By now we know how the trajectory of a rocket is planned and executed. These decisions are spontaneously taken by the rocket control system and implemented instantaneously. “Rocket Propulsion I” was all about the sensitive servo mechanisms that determine the rocket trajectory and the mechanical systems like nozzle displacement and thrust vectoring. This article talks about how a thing, big as a rocket gets the enormous bulk of energy to fly against the gravity and reach the orbit. The answer is the bounty from the dead that we are completely dependent on, for most of our energy requirements, the fossil fuels. Energy sources that may be used in rocket propulsion are solar radiation, radioactivity and chemical energy (in fuels). The solar energy we receive on earth is just not enough to produce the thrust required for the lift-off with the cramped solar energy extraction techniques we have developed.

A radioactive substance is another form of matter charged with high energy density, but the use of radioactive fuels is restricted due to its adverse effects on the environment such as a case of a catastrophic rocket failure. Also, the decay of radioactive fuels is not that fast (even gamma rays from nucleus needs 7-8 secs to cause heating). In short, we haven’t developed any safer and efficient technique to harness solar radiation or energy of radioactive matter (like plutonium, uranium, thorium etc.) for rocket propulsion. Left out with the fossil fuels or some other volatile matter (like gun powder) or artificially developed atomic fuels.

Have you ever wondered, what is there inside a rocket? More than 90% of the rocket’s volume is packed with fuel that burns up as the rocket flies higher and higher into space. Heavier the payload the bigger is the rocket. Along with the fuel, another major component required to excite the fuel and extract energy is an oxidizer.

Broadly the rocket fueling is divided into three major class:

1. Solid fueled rocket

2. Liquid fueled rocket

3. Hybrid rocket

SOLID FUELED ROCKET:

This is the most common and oldest techniques of fueling a rocket. First solid fuel rocket was launched in a war in the 13th century. In solid fuel rockets, the solid fuel and the oxidizer are pre-mixed in solid state and molded to form a cylindrical cross-section with a perforation along the axis of the rocket (cross-section may vary). The burning starts at the perforation and expands outwards. An electrically activated device is used, that produces a flame front hence igniting the propellant. More the surface area of propellant burning momentarily, greater is the thrust.  The various cross-sections provided to the solid propellant perforation majorly affects the variation in the thrust. Continuously increasing thrust is known as the progressive thrust while continuously decreasing thrust is called the regressive thrust; constant thrust being the neutral thrust. Thrust also depends on the burn rate of the fuel and further the burn rate depends on the pressure inside the combustion chamber.

The various cross-sections provided to the solid propellant perforation majorly affects the variation in the thrust. Continuously increasing thrust is known as the progressive thrust while continuously decreasing thrust is called the regressive thrust; constant thrust being the neutral thrust. Thrust also depends on the burn rate of the fuel and further the burn rate depends on the pressure inside the combustion chamber.  As the fuel is burnt inside the combustion chamber due to the presence of an oxidizer, the pressure in the chamber also increases due to the production of the product gasses. The pressure in the combustion chamber is also determined by the nozzle’s dimensions. Besides providing us with large thrust, a solid fuel rocket is cheap and easy to manufacture, it has some major disadvantages too. We cannot control the burn rate of the solid propellant actively during a flight. Also, it’s less efficient than the other class of rockets with no thrust vectoring possible.

As the fuel is burnt inside the combustion chamber due to the presence of an oxidizer, the pressure in the chamber also increases due to the production of the product gasses. The pressure in the combustion chamber is also determined by the nozzle’s dimensions. Besides providing us with large thrust, a solid fuel rocket is cheap and easy to manufacture, it has some major disadvantages too. We cannot control the burn rate of the solid propellant actively during a flight. Also, it’s less efficient than the other class of rockets with no thrust vectoring possible.

LIQUID FUELED ROCKET:

In a liquid fueled rocket the propellant and the oxidizer are compressed and stored in separate tanks  They are combined through sensitive tubing system to give out combustion gases which provide the required thrust to the rocket as they escape through the nozzle. The thrust requirement is purely based on the fuel-oxidizer ratio. Liquid propelled rockets are much more precarious to handle but are the most efficient of all the three.

They are combined through sensitive tubing system to give out combustion gases which provide the required thrust to the rocket as they escape through the nozzle. The thrust requirement is purely based on the fuel-oxidizer ratio. Liquid propelled rockets are much more precarious to handle but are the most efficient of all the three.

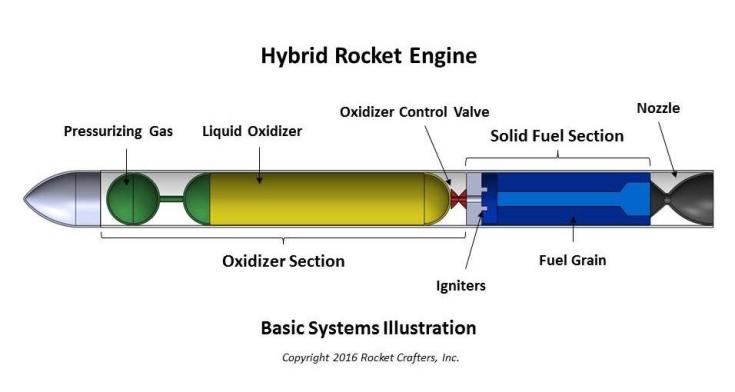

HYBRID ROCKET:

Hybrid engines may have a solid or liquid fuel. The difference is that the oxidizer is not pre-mixed with the propellant but is stored in a separate tank as a compressed liquid.

The advantage of having a liquid oxidizer is that it is more efficient than the solid oxidizer. The oxidizer chamber is attached to the combustion chamber (where the solid propellant is stored with a perforation along the axis leading to the nozzle of the rocket, from where the product gases escape), via insulated tubing with an injector at the other end. The oxidizer is allowed to flow through the tubes through a valve which controls the combustion by limiting the amount of oxidizer to the combustion chamber. Its best suited for rockets as the thrust is controlled at any instant by limiting the flow of oxidizer into the combustion chamber; contradictory to the solid fuel rocket.

COMMON FUELS AND OXIDIZERS USED:

Oxidizers: liquid oxygen and liquid fluorine, nitrogen tetroxide, hydrogen peroxide.

Solid fuels: Earliest rockets were powered by gun powder(charcoal). Ammonium perchlorate composite propellant (APCP) is the most common solid propellant used. Sucrose, zinc-sulfur are some more solid propellants.

Liquid fuels: Liquid oxygen (LOX), liquid hydrogen (LH), kerosene (RH-1) and methane are some of the commonly used liquid fuels.

The above mentioned are a few perennial rocket fuels; otherwise, there’s a big list of propellants scientists discover every day with varying properties, but I don’t feel like mentioning all the creepy chemical names here and get your brains out of your head.

WHY HYBRID ROCKETS ARE VIABLY USED?

Oxidizer used in a solid fuel rocket is premixed with the propellant; hence the oxidizer needs to be in the solid form which is done by bonding oxygen atoms to nitrogen producing solid potassium nitrate which obviously is not that volatile as elemental oxygen, reducing the efficiency of a solid propelled rocket. Also, the energy density of solid fuels is much more than the energy density of the liquids and hence making hybrid mechanism a much-preferred means of propelling rockets.

MULTI-STAGE SEPARATION:

As the rocket exhaust’s its fuel it gets lighter and reaching the outer orbits it requires much less thrust from the left-out fuel. The required thrust after most of the fuel is exhausted is quite low due to the reduced mass. Generally, rockets use multistage separation technique. In this approach, the fuel tanks are separately made and assembled to make up a huge rocket tank (each sub-set having its own governing system and thrusters. As the rocket ascends it ejects the lower subset (emptied tank) to release the dead weight. Now the nozzles in the subset one activate. Similarly, the rocket may give off more emptied tanks to reduce weight on its entire flight.

Next version will include the non-conventional rocket technology and propellant used by Space-X and a briefing of the launch sequence of a rocket from assembly to the lift-off.

…to be continued.

Excellent review on such a interesting topic

LikeLiked by 1 person